RESOURCES

How Board Mount DC/DC Converters Are Used in Medical Applications

The term "medical devices" can encompass a wide range of technologies, from sensors placed on the skin or in the body to cauterization tools used during surgery. One thing they all have in common is the need for assured electrical safety in a small package. Engineers often use board-mount DC/DC converters in medical power supplies to provide proper isolation and prevent patients and operators from lethal electrical shocks.

We'll go over the electrical demands of medical devices, how AC/DC and DC/DC converters can help, and other things to keep in mind when designing a medical appliance.

Safety Regulations for Medical Devices

Of course, medical devices are highly regulated by governments and standards development groups. These robust regulations are critical for protecting patients and operators — such as nurses and doctors — from experiencing lethal shocks. Some standards you'll likely need to meet include:

- ANSI/AAMI ES60601-1: This United States standard comes from the American National Standards Institute (ANSI) and the Association for the Advancement of Medical Instrumentation (AAMI). It specifies basic safety and performance requirements for medical electrical equipment and is recognized by the U.S. Food and Drug Administration (FDA).

- IEC 60601-1: The International Electrotechnical Commission (IEC) has a similar version of the ANSI standard aimed at an international audience.

- MDR 2017/745: This Medical Device Regulation (MDR) is a standard used in the European Union for medical devices. It replaced Medical Device Directive (MDD) 93/42/EEC.

These standards usually outline technical requirements and any additional demands like risk analysis. Technical requirements generally include a double-safe electrical separation between any high energy sources or hazardous voltages and the patient or operator. These devices need two means of protection (MOP) — also called measures of protection — including means of operator protection (MOOP) and means of patient protection (MOPP). Of the two, MOPP is more stringent, since patients are more likely to be vulnerable and unable to handle the shock.

Why Isolation Is Essential for AC/DC Converters

When using an AC/DC converter, isolation is always necessary. If the power supply fails, it protects patients from being shocked with lethal voltage. It also ensures patients can receive high voltage during some procedures, such as cauterization or defibrillation.

Medical devices have specific isolation requirements to ensure patient safety. AC/DC converters often have some type of isolation, but these mechanisms don't always meet the strict demands of medical devices. For instance, they might lack one means of protection or have a high isolation capacitance that doesn't meet low leakage current demands.

The applied part of a medical device is the part that contacts the patient. Isolation requirements vary by the type of applied part used. These include:

- Body (Type B): Type B parts have the least strict requirements since the patient can usually let them go quite easily. Some examples include phototherapy equipment or hospital beds. They are typically non-conductive and can be grounded.

- Body floating (Type BF): These parts usually have some conductive contact with the patient. These parts are floating and have no ground connections. Examples include ultrasound equipment and blood pressure cuffs.

- Cardiac floating (Type CF): With the strictest requirements, Type CF parts can come in contact with the heart or bloodstream, such as dialysis and surgical equipment. Like Type BF, these parts are floating and aren't grounded.

When Do DC/DC Converters Also Need Isolation?

Although not always required for functionality, DC/DC converters in medical supplies may also need isolation in some situations, such as:

- Breaking ground loops

- Providing additional patient or operator safety

- Providing a negative rail from a positive supply

- Reducing the effects of electromagnetic interference (EMI)

How to Create a Medically Approved System Using an AC/DC Converter and DC/DC Converter

Although you can find AC/DC converters that meet medical standards, they are generally expensive. Combining AC/DC and DC/DC converters can provide a more affordable option.

One way to meet medical safety standards is by combining an AC/DC converter and a DC/DC converter in the right series. For example, you can follow an IT-grade AC/DC converter with an isolated, medically-approved DC/DC converter that delivers power to just the patient- or operator-accessible components. However, you would need to select the AC/DC converter carefully to ensure it meets the medical specifications, such as EMI suppression. If the leakage current for the AC/DC converter exceeds leakage current requirements, you could add additional EMI controls, for instance.

The Benefits of Using a DC/DC Converter for Medical Applications

The primary benefit of opting for a DC/DC converter is that it adds an extra layer of protection between the patient and any equipment they're connected to. During the risk analysis process, you must consider the worst-case scenario of what happens when equipment fails. If not adequately isolated, the patient or operator could experience electrocution or burns. While the connections to a patient must be isolated from the ground, DC/DC adds another level of isolation between the patient or operator and an external signal fault condition.

For example, while it can be difficult to keep leakage levels within the required specifications on an AC/DC converter, DC/DC converters can easily accommodate low leakage currents. You could power the patient connection from a DC/DC converter that meets the right demands. You'll need to consider what types of connections you're working with and the style of grounding to choose adequate isolation technologies.

In general, meeting medical specifications, particularly 2MOP, through a DC/DC converter is generally more cost-effective than trying to do so through an AC/DC converter.

Other Specifications to Consider

Isolation specifications are crucial, but you'll also need to consider how your medical appliance will meet other specifications, such as:

- Creepage and clearance distances: Observing creepage and clearance can help prevent the possibility of a stray path from a high-voltage connection to one that would need to be isolated. You can avoid excessive voltage gradients between system parts by achieving creepage and clearance distances. Since medical devices often have size limitations, you may have minimal board space to work with, which can add complexity to board mount applications.

- Product and internal transformer temperatures: You will also need to analyze risk to reduce heat and fire hazards by keeping internal temperatures down. Keeping them as low as possible compared to ambient temperatures can increase the overall reliability of the converter.

- Cooling mechanisms: Cooling is vital when designing a converter and is often overlooked in converters that are primarily operated in standby mode. When powered up, the converter must be ready to respond to internal or external control signals requesting power conversion cycles. Often, the load is only applied occasionally. Heat flow from the converter must be established so the temperature doesn't increase to unsafe levels. Bear in mind that even in standby mode, the power supply may be dissipating power in the form of heat. This heat must be allowed to flow via a low thermal resistance path to the ambient, otherwise, the system will get very hot.

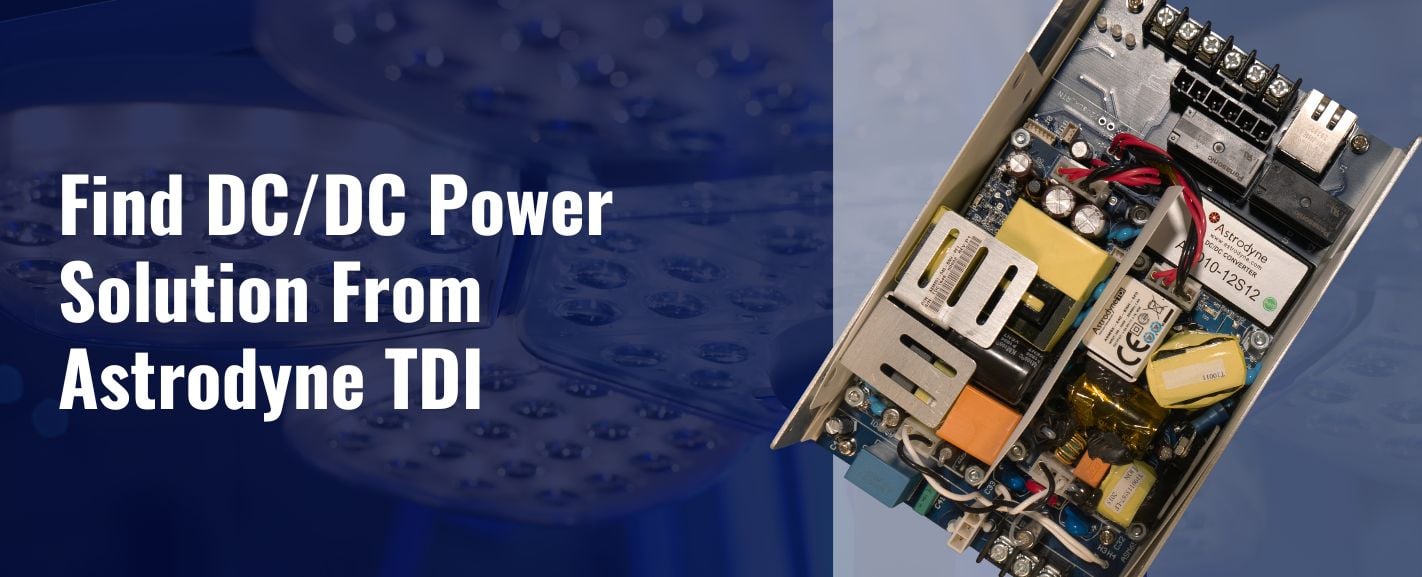

Find DC/DC Power Solutions From Astrodyne TDI

Astrodyne TDI is a leader in power solutions, with DC/DC power supplies perfectly suited to the medical industry's strict requirements. We've put over six decades of experience to work in providing reliable power delivery across a wide range of installations. We have ISO 9001 and ISO 13485 certifications, so you can be confident in the quality and consistency of Astrodyne TDI products.

Explore our DC/DC power supplies online, or reach out today to chat with an expert about your medical appliance.