RESOURCES

What Is the Future for GaN and SiC in the Semiconductor Industry?

The semiconductor industry has made significant strides in the past few decades, working toward smaller sizes and greater efficiencies. Wide bandgap semiconductor materials have been of specific interest, which has provided significant improvements in performance over the current standard, silicon.

Gallium nitride (GaN) and silicon carbide (SiC), have a promising future in the power electronics industry. Below, we will discuss the benefits of wide bandgap semiconductors applied to power supplies and compare the use cases of GaN and SiC.

What Are Wide Bandgap Power Supplies?

Transistors are the core of today's electronics and present a significant portion of the semiconductor industry. These devices amplify or switch electronic signals and electrical power. In a perfect world, the transistor would switch at infinite speeds with zero on- and off-state resistances. While the perfect switch doesn't exist, material scientists are working with various materials to achieve one as close to perfect as possible.

This means they have to look at several material capabilities, such as voltage, current, switching speed and bandgap width.

The bandgap of a semiconductor material defines the amount of energy (electron Volt) required to move an electron from the valence band to the conduction band and begin acting as a conductor.

For decades, the primary material used for semiconductors has been Silicon, which has a bandgap of 1.2eV. Wide band materials like SiC and GaN require a larger energy (approximately 3.2 ev) applied to conduct. This means a wide band gap (WBG) material can be thinner than Silicon to sustain the same voltage applied. Thinner WBG material results in lower conduction and switching losses compared to Silicon of equal voltage rating.

The reduced switching losses allow for higher switching speeds, resulting in smaller, more efficient power supplies. Reduced losses also mean the WBG material does not heat up as much as silicon. Failure modes for semiconductors are largely due to thermal stress. Reducing the thermal stress in the semiconductor, you increase its lifetime and the reliability of the supply. This makes WBG devices highly desirable in power semiconductors and future electronic applications.

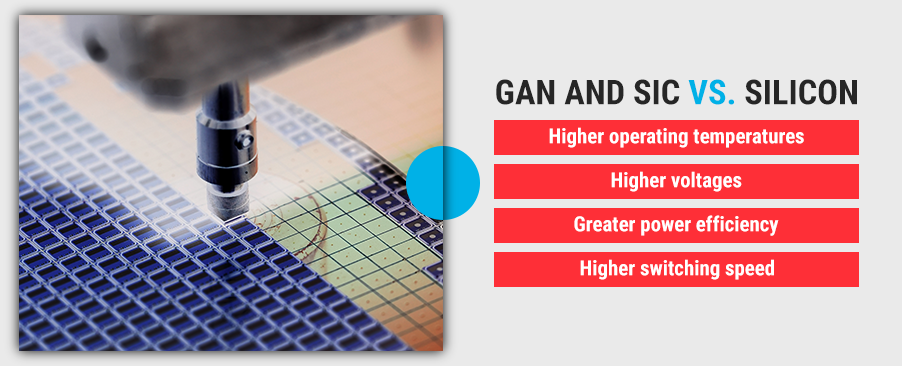

Advantages of GaN and SiC vs. Silicon

Advantages of GaN and SiC vs. Silicon

Silicon carbide and gallium nitride are the two most significant wide bandgap materials in the semiconductor industry. Compared to silicon's bandgap of 1.1 eV, SiC's bandgap is 3.3 eV, and the gallium nitride bandgap is 3.4 eV. This wider bandgap lends both materials the following advantages over silicon:

- Higher operating temperatures: Wide Band Gap materials can operate at higher temperatures as compared to standard Silicon. In general, wide band gap devices can operate up 200°C as long as the package can tolerate this, while Silicon is limited to 150°C. Thermal conductivity is a material's ability to transfer heat and relates directly to the material's temperature during use. Material inefficiencies generate heat during high-power applications, and the more heat a material retains, the more its electrical characteristics change. Gallium nitride's thermal conductivity is 1.3 W/cmK, while silicon carbide has a thermal conductivity of 5 W/cmK. Therefore, SiC is advantageous in high-power and high-temperature applications.

- Higher voltages: The breakdown field is a measure of the dielectric strength of a material after the material takes in enough energy to breach the bandgap. Gallium nitride's breakdown field is 3.3 MV/cm, while silicon carbide is 3.5 MV/cm. Silicon's breakdown field, on the other hand, is 0.3 MV/cm. The higher breakdown field makes both SiC and GaN nearly 10 times more capable of handling higher voltages.

- Higher switching speed: Wide bandgap materials tend to possess higher electron mobility and electron saturation velocity, allowing for switching frequencies up to 10 times higher than silicon. Electron mobility describes how quickly electrons can move through a material. Gallium nitride boasts an electron mobility of 2,000 cm^2/Vs, while SiC offers an electron mobility of 650 cm^2/Vs. GaN's high electron mobility makes it suitable for high-frequency applications.

Both materials are similar in their bandgap width, although SiC and GaN serve different power applications. Their differing characteristics determine which applications each of these materials are best suited for. GaN is often pursued for low-power and high-frequency applications, while SiC is used in high-power and high-voltage applications. GaN chips are used in 30- to 600-volt devices, while SiC field-effect transistors (FETs) are used in 600-volt to 10-kilovolt applications.

SiC is currently being used to replace 1200V silicon IGBTs and MOSFETs. These higher switching IGBTs have been used in several Astrodyne TDI power supply designs. Critical applications demand higher power density to save high dollar value space. By achieving 18W/in3, AstrodyneTDI has helped numerous customers optimize their design to save on space.

The Future for GaN and SiC in the Semiconductor Industry

One significant question in the sector is whether GaN and SiC will replace MOSFETs and insulated-gate bipolar transistors (IGBTs). Experts in the field say the more realistic future is that the technologies will exist side-by-side for some time.

Astrodyne TDI has been increasing the use of SiC MOSFETs over the past decade, and our Research and Development Team is deploying GaN technologies in new niche designs. Silicon FETs will certainly remain a critical piece in our supply chain, but we are excited about the design enhancements we continue to make thanks to wideband gap technologies.

GaN and SiC power semiconductors are expected to make significant strides in the power industry within the next decade. At present, the primary limiting factor for GaN and SiC is production cost. Production of large-diameter SiC and GaN wafers is limited, with high rates of defects and expensive manufacturing processes compared to silicon. Despite this, great strides have been made to improve manufacturing processes in recent years, resulting in SiC and GaN slowly moving into their respective niches in the industry.

Utilizing these transistors in our power supply designs, Astrodyne TDI is pacing to achieve close to 40W/in3. This density would not be possible without SiC technology. Astrodyne TDI’s next-generation three phase programmable power supply will deliver 5.5kW of power in a 2U liquid-cooled embedded power supply.

While SiC and GaN are gradually making their way into the industry's low-power segments, they are already competing in the high-power arena. In the sector's high-power segment, SiC and GaN compete against IGBTs and super-junction MOSFETs. Analysts predict GaN and SiC will have a consolidated share of 13% in the power semiconductor market by 2024.

GaN and SiC Frequently Asked Questions

Choose Astrodyne TDI

If you're interested in learning more about the uses of GaN and SiC and the benefits of GaN and SiC power applications, Astrodyne TDI can help.

Astrodyne TDI produces power supplies and EMI/EMC/RF filters for various markets, from the aerospace and military sectors to the medical and semiconductor manufacturing industries. With over 60 years of experience in production and custom design, you can trust us to create highly reliable and durable products that meet your exact specifications.

Learn more about SiC and GaN power device potential for your company by contacting Astrodyne TDI today.