RESOURCES

Modern Alternatives to Thyristor Based Electronic Heater Controls

Replacing Silicon-Controlled Rectifiers (SCR)/Thyristors with Switch Mode Power Supplies (SMPS)

Switch mode power supplies provide two main advantages over SCR/ Thyristor power supplies, smaller and lighter assemblies for comparative power output and better input harmonics and quality. In this article, we argue that replacing SCR/Thyristors with switch mode power supply can optimize your equipment and process while providing increased switching frequency for greater power density.

SMPS VS. SCR: Isolation Transformers

In galvanically isolated SCR power supplies, much of the weight and size of the supply is dedicated to a large laminated iron core transformer. This transformer is used to convert the 50-60 Hz AC Input voltage from the grid into an appropriate secondary AC voltage that can then be rectified to produce the DC output voltage. These large transformers are not required in switch mode power supplies resulting in space and weight savings. In a high-frequency SMPS, this isolation is achieved in much smaller ferrite core transformers used in conjunction with a circuit known as a full bridge converter.

The full bridge converter switches the polarity of the voltage across the ferrite core transformer much faster than the 50-60 Hz available from grid voltage. High-speed switching is the key to reducing the size of the isolating transformers. A 60 Hz transformer capable of delivering 3 kW has a volume of >500 cubic inches, resulting in a transformer power density of 6 W/In3. Whereas the transformer used in ATDI’s 3.8 kW Mercury Flex SMPS, operating at nearly 150 kHz, has a volume of 8 cubic inches. This results in a transformer power density of 475 W/In3. This reduction in transformer size translates directly to reduced system size and weight.

SMPS VS. SCR: Harmonics Current

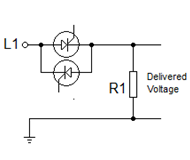

In non-isolated, phase-regulated SCR supplies, the output current is controlled by varying the portion of the 60 Hz sine wave that is delivered to the load. The figure below shows the delivered current for different conduction angles of the SCR. For a higher average output current, the SCR conducts earlier in the cycle; while for a lower average output current, the SCR conducts later in the cycle.

-png.png)

Figure 1 - Current applied to R1, comparing different SCR conduction angles

A consequence of this is that electrical current is only conducted when the SCRs are passing current to the output, this results in poor input harmonics since the current waveform is not a continuous sine wave.

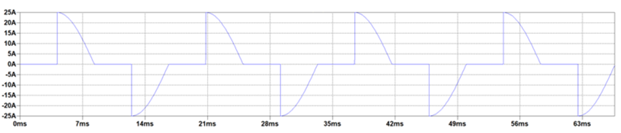

For example, in the case where the SCR conducts during the peak of the sine wave for both positive and negative half cycle; the current quickly transitions from zero amps to the maximum.

Figure 2 - Output Current with SCR conduction angle at peak of half cycle

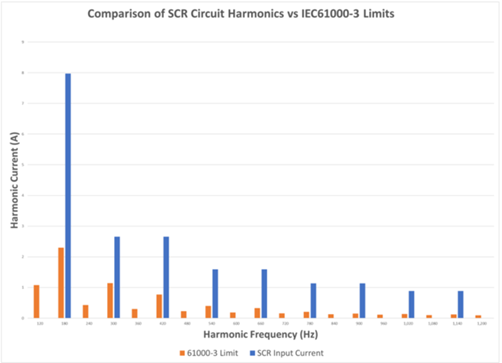

The resultant waveform shown above in Figure 2 can be further examined using Fourier analysis. This mathematical process breaks any waveform into an infinite summation of sinusoids with varying magnitudes and frequencies. What we find with this process is that in the example above, a large component of the current resides in the third harmonic of 180 Hz. Figure 3 below shows the magnitudes of the harmonic currents for the even and odd harmonics of 60 Hz. These levels are well above the IEC61000-3 limit.

Figure 3 - Harmonic current content of waveform shown in Figure 2

In addition to these individual harmonic levels being over the limits, the aggregate or Total Harmonic Distortion (THD) is 63%. The IEC61000-3 limit for THD is 15%.

ATDI’s 3.8 kW Mercury Flex SMPS utilizes an active power factor corrector or PFC. This circuit monitors the input voltage and current and ensures they are both in phase with each other and are continuously sinusoidal. The Mercury Flex has a THD of 9.57% at an output power of 3.8 kW, well within the 15% limits for IEC61000-3.

High-Frequency SMPS: MERCURYFLEX

An Air-Cooled Power Solution by Astrodyne TDI

SCR/Thyristor power supplies were largely used before fast switching transistor technologies were developed, however, high-frequency SMPS supplies are a fully mature technology that provides a better solution in applications that demand unique output voltage and current programmability. ATDI’s MercuryFlex SMPS provides precise output voltage and current set points via analog signals or digital communication.

This ability to control the voltage or current applied to a load at any time, in conjunction with the greater power density and superior input harmonics, makes ATDI’s MercuryFlex an excellent alternative to aging SCR/Thyristor based power supplies. Contact your local ATDI representative today to learn more about the MercuryFlex Power supply!

Key Takeaways:

- SMPS are smaller and lighter power supplies due to the increased switching frequency and offer significantly greater power density

- Power factor correction can be achieved in space-saving active PFC converter as opposed to static compensator networks

- Better harmonics are achieved through the use of an active PFC converter

Value Added Power Solution by AstrodyneTDI:

- The easily adjustable output voltage, current, and power with MercuryFlex/ LiquaBlade products

- The modular approach makes power scalability simple

- Digital communications available through Ethernet