RESOURCES

High Slew Rates: Solutions for Semiconductor & Laser Applications

In specific manufacturing processes, a pressing need arises for swift programming and precise response to output load transients. This necessity is particularly critical regarding the power source that fuels these processes.

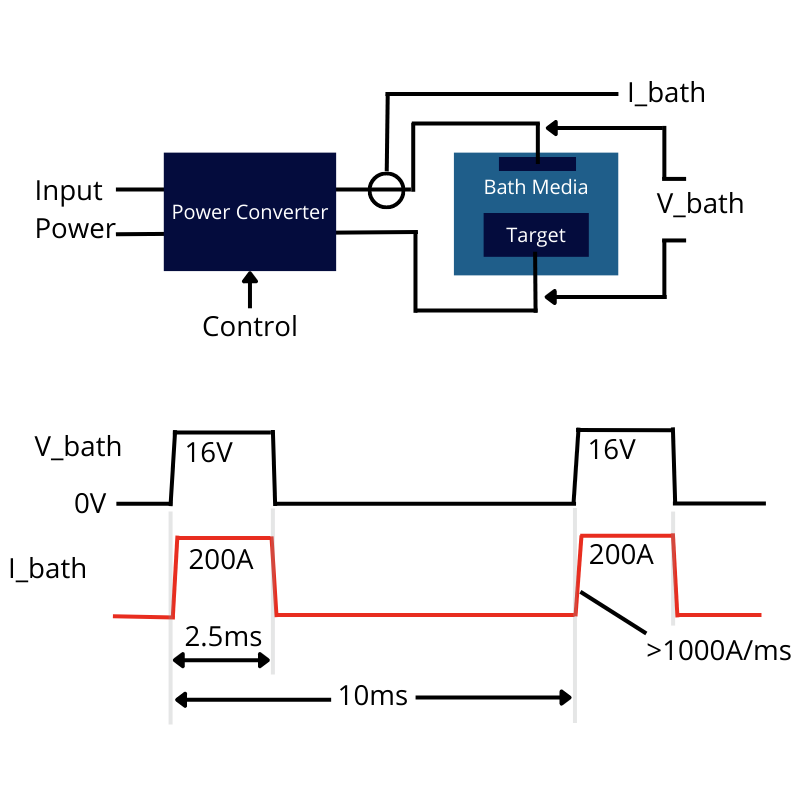

Consider, for example, semiconductor laser applications that require pulse currents in the hundreds of amperes, with transition rates reaching an astounding 1000A/ms. Similarly, pulse plating and beam steering applications call for bipolar currents with both rapid transient times and stringent accuracy requirements.

To tackle these demanding challenges head-on, this blog post delves into offline power sources supporting output slew rates that meet and surpass the specified criteria (>200V/ms; >1000A/ms).

Challenges in Achieving High Output Slew Rates

When delivering DC power, offline power supplies face a challenge in filtering out disruptive AC line frequency signals. This filtering process often involves an output capacitor, which inadvertently slows down the response time of the output voltage to changing conditions. As a result, applications that rely on rapid slew rates for voltage and current delivery can be hindered.

| Semiconductor Laser Application | Pulse Plating Application |

|

|

|

PRF: 5kHz Peak Power: 10.25kW RMS Power: 7.25kW Average Power: 5.13kW |

PRF: 100Hz Peak Power: 32kW RMS Power: 16kW Average Power: 8kW |

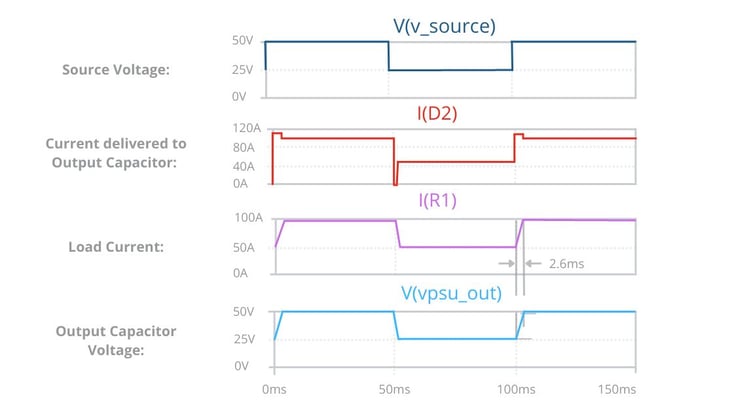

To gain insights into the impact of typical offline PSU output filters and over-current protection circuits on the delivered slew rate, a fascinating LTspice simulation was conducted. Assuming an instantaneous response from the control loop and main voltage generator, the simulation revealed excellent results. With an output filter capacitor of 4000uF, an OCP set at 110A for a 100A-rated PSU, and accounting for 10uH of load cable inductance, the transition from 25V to 50V showcased an excellent rise time of just 2.6ms and an impressive output slew rate of 15A/ms. These findings highlight the capabilities of offline power sources in meeting the demanding requirements of high output slew rates in semiconductor and laser applications.

The effects of PSU output capacitance on slew rate are significant. Minimizing the output capacitance by approximately 90% compared to standard offline power supplies makes it possible to achieve remarkable slew rates exceeding 200V/ms.

However, achieving high slew rates comes with its challenges. The output capacitor limits the discharge time of the output, while the output choke restricts the charge time. Additionally, the control loop limits the response time, presenting further hurdles in pursuing high slew rates.

| High-Frequency Switch Mode Converter |

.jpg?width=549&height=206&name=Illustration%20of%20Typical%20Off-Line%20PSU%20Output%20Capacitor%20Effects%20(4).jpg) |

The operation of power supplies from AC power lines often requires an extensive output filter (L+C) and control loop with a moderate gain crossover bandwidth to suppress ripple and maintain stable operation. Unfortunately, these requirements limit power supplies, making it challenging to support applications requiring ultra-high slew rates. Typically, the maximum dynamic output frequency is 10Hz or less, while the output slew rate is less than 10V/ms or 100A/ms.

.jpg?width=800&height=300&name=Illustration%20of%20Typical%20Off-Line%20PSU%20Output%20Capacitor%20Effects%20(5).jpg)

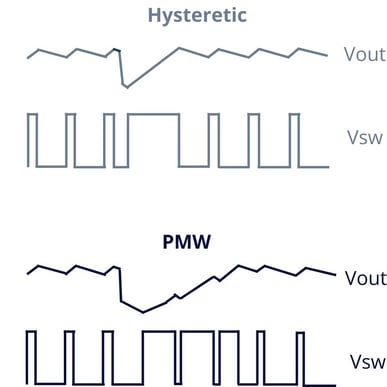

Achieving optimal performance in power supplies requires careful optimization of the post regulator. The converter must possess specific characteristics such as a quick control loop response time, minimal output capacitance, and minimal filtering inductance to achieve high slew rates. One effective solution is implementing a high-speed Hysteretic-control high-frequency switch mode post converter between the AC-DC power supply and the load. This converter not only provides a bipolar output, which is essential for plating and beam steering applications, but it also acts as a fundamental building block that can deliver impressive voltage and current levels.

|

High-Frequency Switch-Mode Post Regulator: |

.jpg?width=648&height=243&name=Illustration%20of%20Typical%20Off-Line%20PSU%20Output%20Capacitor%20Effects%20(6).jpg) |

What sets this converter apart is its ability to operate with minimal output capacitance and filter inductance, resulting in an output that exceeds 1000V/ms and 2000A/ms. With an efficiency rate of over 98% and a compact size, these converters can be easily scaled and modularized to meet the specific needs of semiconductor and laser applications.

Hysteretic control offers significant benefits compared to traditional pulse width modulated power supplies. Unlike PWM control, the slew rate of a Hysteretic controlled converter is not confined by its closed-loop bandwidth. This means it enables a remarkably faster rise time for output current. The output inductor and input voltage overhead determine the minimum rise time, allowing for precise control over the wind's speed.

Furthermore, the slew rate of a Hysteretic controlled converter is independent of the control loop bandwidth, providing the flexibility to select the optimal switching frequency range for achieving the highest efficiency at different load conditions. This versatility revolutionizes power supplies, delivering exceptional performance for various applications.

High Slew Rate Solution: Exemplary Performance Demonstrations

|

Scenario #1 |

|

|

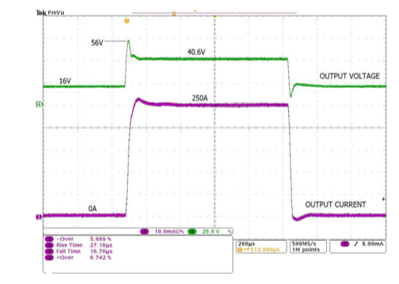

0-250A Into Diode Load / 5kHz Rep Rate

|

In a cutting-edge semiconductor laser application, the power of eight assemblies connected in parallel comes together to achieve an astonishing slew rate of over 4000A/ms. This breakthrough performance showcases the immense capabilities of these power supplies in meeting the demanding requirements of high output slew rates. |

|

Scenario #2 |

|

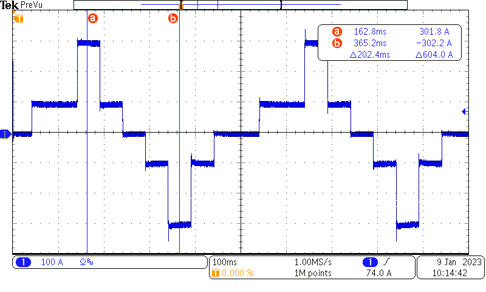

|

Three assemblies are interconnected in a parallel configuration, forming a powerful setup for a pulse plating application. This setup offers a programmable bipolar output, allowing precise control over the current flow. The output is commanded to transition from 0 to +100 to +300 to +100 to 0 to -100 to -300 to -100 to 0A, with each transition occurring within a 500ms period, equivalent to a frequency of 2Hz. This remarkable configuration showcases the versatility and adaptability of these power supplies in meeting the demanding requirements of high output slew rates. |

Navigating Connection Inductance

The presence of connection inductance in the load can create a hurdle regarding the current's rise time. Typically, the estimated inductance is around 15uH or even higher. Additionally, any inherent inductance in the converter further adds to this limitation. To achieve a rise time of 2000A in less than 1 ms, the power supply source voltage must surpass the voltage needed to sustain the load.

.jpg?width=358&height=358&name=Pulse%20Plating%20Application%20(1).jpg) This requirement establishes the minimum link voltage between the AC-DC converter and the AWG (Arbitrary Waveform Generator), ensuring optimal performance and efficient operation.

This requirement establishes the minimum link voltage between the AC-DC converter and the AWG (Arbitrary Waveform Generator), ensuring optimal performance and efficient operation.

Precision in Delivered Currents

The AWG utilizes high-quality Hall Effect sensors to control and measure the delivered current accurately. These sensors undergo meticulous calibration to ensure precise performance. The initial tolerance guarantees that the zero output offset is calibrated within a range of +/-10mA, which is an impressive 0.02% of the 50A output. Additionally, the gain slope is calibrated to ensure that the maximum current, Imax, reaches 50A with a tolerance of 100mA, equivalent to 0.2%.

It is worth noting that the temperature rise of the Hall Effect sensor may introduce a minor error of 0.8% at full output power over the operational temperature range. However, this error is negligible and does not significantly impact the overall accuracy. A 12-bit system typically achieves a resolution of 25mA per bit, providing exceptional precision. Furthermore, achieving even higher resolution with higher bandwidth control interfaces is possible, enabling enhanced control and measurement capabilities.