RESOURCES

Switching From SCR to Switch Mode Power Supplies

The right power supply could present a hidden opportunity for energy savings. While SCR power supplies have been invaluable for power regulation in many applications, they are bulky, require heating and cooling, and lack the efficiency of switch mode power. The global market size for switch mode power supplies is expected to reach $26.88 billion by 2024 as more businesses realize the benefits of investing in the transition.

Understanding the differences between SCR and switch mode power supplies is a critical step in making the transition successfully.

What Is an SCR Power Supply?

A silicon-controlled rectifier (SCR) power supply, or thyristor with an additional anode gate, is a device widely used for AC and DC power control. It's used in many industrial applications, such as reversing speed control for DC motors. An SCR has a gate in addition to an anode and a cathode. Users can control the phase of the gate signal, regulating the average power delivered to the load. The device only starts to conduct forward when a signal is applied to the gate.

The primary function of an SCR power supply is controlling the flow of electricity in a single direction. A dimmer switch is an excellent example of how the process works. This traditional power regulation technology is also common in motor control.

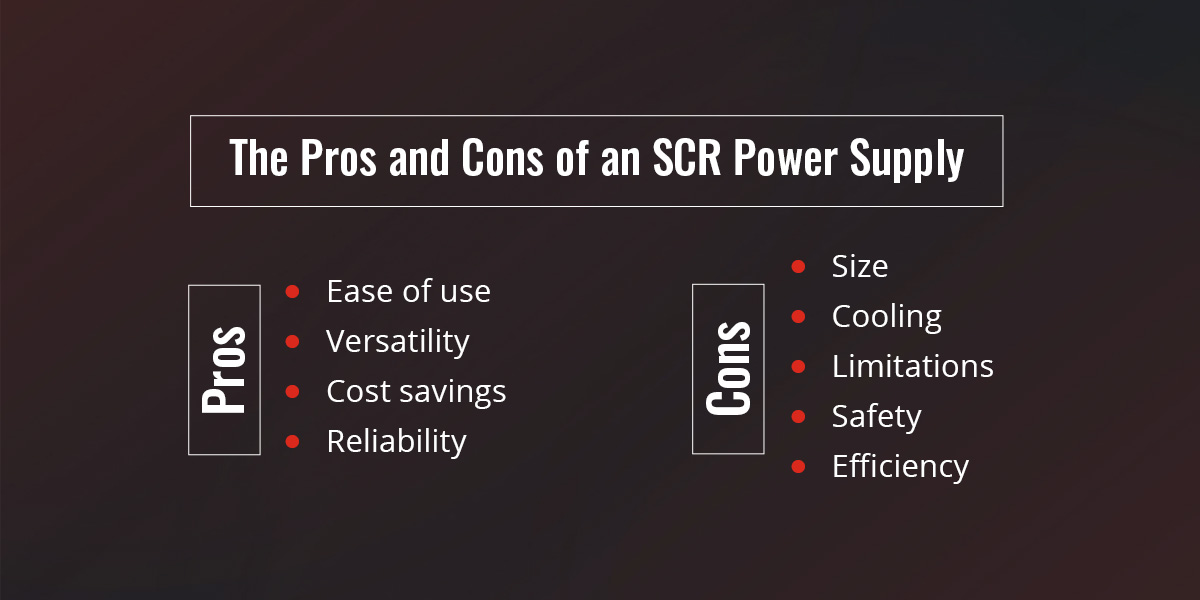

The Pros and Cons of an SCR Power Supply

While SCR power supply is a more traditional form of power regulation, it still has advantages and applications:

- Ease of use: An SCR has a basic triggering circuit. It's easy to turn on and simple to use.

- Versatility: This power supply can control both AC and DC power.

- Cost savings: SCR power supplies are a relatively cost-effective investment, particularly for large-scale operations.

- Reliability: It's easy to protect an SCR with a fuse, and it can handle large voltage, current, and power.

Despite the advantages, this option has significant drawbacks, including:

- Size: Many SCR units are bulky and take up space.

- Cooling: SCR power supplies require air and water cooling.

- Limitations: SCR power supplies can only control power in one direction, so they are limited to one-half cycle of AC. The maximum frequency of their operation is 400 Hz, making them unsuitable for operation at high frequencies. The gate current cannot be negative.

- Safety: The power supply can turn on accidentally due to the high DV/DT source voltage.

- Efficiency: The energy output levels of SCR power supplies decline during heavy production, resulting in wasted energy and impacting overall efficiency during operations.

What Is a Switch Mode Power Supply?

A switch mode power supply (SMPS) incorporates switching regulators to efficiently convert electrical energy. In contrast to linear power supplies, the pass transistor of an SMPS constantly switches between low dissipations, full-on, and full-off. It's only in high-dissipation transitions when necessary, minimizing waste electricity.

Switch mode conversion applies to both AC and DC power supplies, although they are a popular method for DC-DC power conversion. The input power supply is fed to an inverter, where it's turned on and off at high frequencies by switching the metal-oxide-semiconductor field-effect transistor or power transistor. A feedback circuit monitors the output voltage and manages the control circuit adjustments, maintaining the output at the required levels.

SMPSs have considerable benefits and can be found in many applications, especially compact electrical appliances. Many compact switch-mode power supplies are reliable and robust for medical and industrial applications.

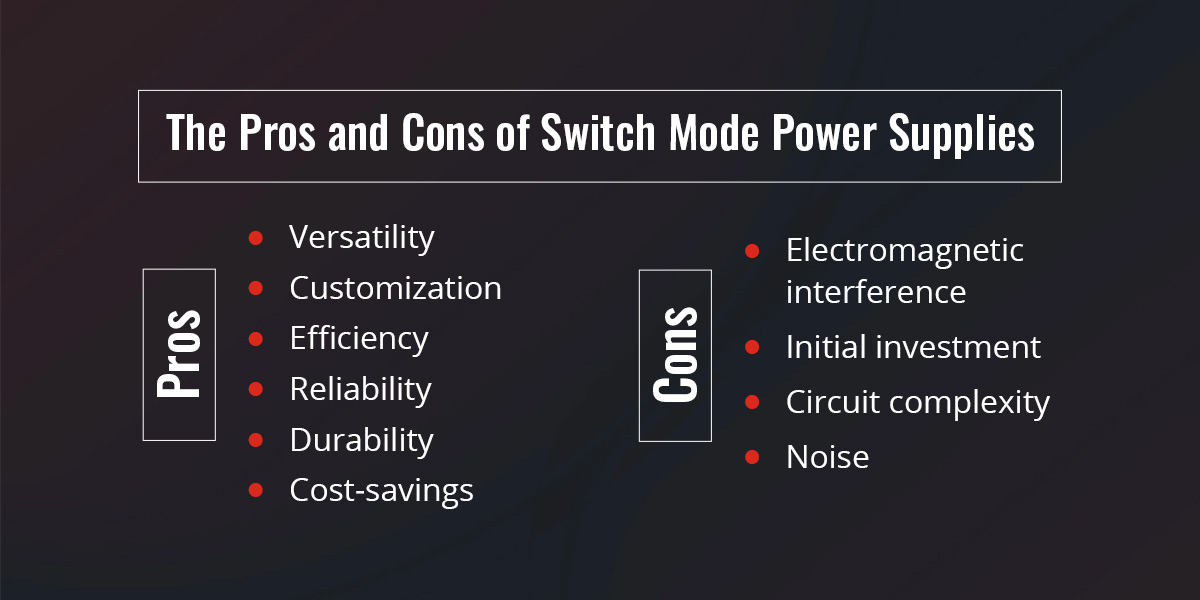

The Pros and Cons of Switch Mode Power Supplies

An SMPS has considerable advantages across many applications:

- Versatility: You can select one of many SMPS topologies, including step up, step down, and invert. Whatever the application, you can adjust the topology to fit almost every output voltage.

- Customization: SMPSs are designed with varying integration levels, allowing engineers to select the appropriate features. Astrodyne TDI reduces the design burden for application-specific power supplies or creates custom options for unique project requirements.

- Efficiency: High efficiency is one of the principal advantages of SMPS designs, minimizing power loss and reducing thermal management requirements. As components are not subjected to excessive heat, they also reduce maintenance requirements and boost system longevity.

- Reliability: The circuit complexity in SMPS results in regulated and reliable outputs, regardless of input voltage variations. They offer high power density and are lightweight and easy to move, making them suitable for many mobile applications.

- Durability: Many SMPSs have additional control features combined with robust environmental, corrosion, and lightning protection, making them an ideal choice for challenging outdoor environments.

- Cost-savings: The reliability and durability of SMPSs reduce field support and maintenance requirements, and their compact size allows for easy cleaning.

Like all energy regulation systems, an SMPS has some drawbacks, including:

- Electromagnetic interference: Some SMPSs generate electromagnetic interference, making them unsuitable for applications that require a clean electromagnetic environment.

- Initial investment: SMPSs require a higher upfront investment than linear power systems.

- Circuit complexity: While greater circuit complexity makes SMPSs more dynamic, it requires expert design and maintenance to ensure safety and effectiveness.

- Noise: An SMPS operates at higher frequencies than an SCR power supply, and the high-frequency switching results in electrical noise.

SCR vs. Switch Mode Power Supplies

SMPSs and SCR power supplies have significant design differences. SCRs have fewer power conversion steps, while SMPSs are more complex and produce DC at a much higher operating frequency, making them more efficient. SMPSs are also considerably lighter, easier to work with, and generate less heat, resulting in minimal power wastage.

From a business perspective, the improved efficiency and flexibility of SMPS are essential. They lower the consumption of cooling resourcing and perform at higher electrical efficiency, reducing overall operating costs and fitting seamlessly into many environments. As they operate at a higher frequency, SMPSs allow a tighter configuration while delivering the same overall power or more.

What to Expect When You Switch From SCR to Switch Mode Power Supplies

Transitioning to a different power supply can be complex, depending on the project's size, scope, and budget. Working with an experienced manufacturer that understands your needs can shorten the process, but it's best to be aware of additional elements, like maintenance changes and potential downtime.

SMPS are more complex, so your maintenance requirements must change to keep your system running optimally. Although the systems are reliable, they have more moving parts, and your team must monitor performance carefully. In addition, the transition requires careful planning to avoid potential downtime. Consulting a team of experts is the best way to keep your operations running throughout the transition.

Streamline the Transition to SMPS With Astrodyne TDI

An efficient, reliable, and versatile power supply is crucial to many applications, from medical and industrial to military and aerospace. You enjoy considerable cost savings when you can regulate your electricity output specifically to what you need.

Astrodyne TDI has decades of experience as an industry leader in meeting business power needs. Whether you want to upgrade your current power supply or require a customized option for a unique project, let us worry about the power so you don't have to. Contact us to learn more about switching to SMPS or request a quote and start your transition today.