RESOURCES

Case Study: Scalable Power for Next-Gen Phased Array Antenna Systems

From Concept to Capability: Supporting a Mission-Critical Defense Program

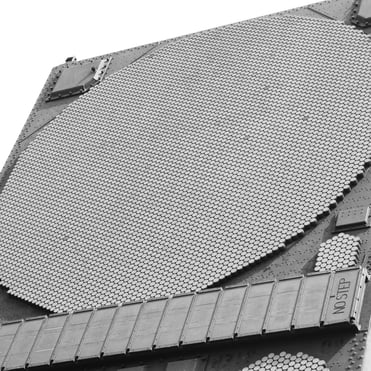

A defense prime contractor was tasked with developing a new Multi-Band, Multi-Mission Phased Array Antenna System to operate across land, sea, and air platforms. The system demanded cutting-edge performance, dense power distribution, and absolute reliability in mission-critical environments.

Rather than treat power as an afterthought, the customer brought in Astrodyne TDI early in the design process to ensure the electrical architecture would scale with the system and meet the rugged operational demands. Our engineering team became an embedded part of their development effort, allowing the customer to focus on antenna performance and system-level innovation while we handled the power delivery architecture.

The Challenge: High-Density, High-Reliability Power in a Compressed Timeline

As the phased array system architecture evolved, so did its power demands. The program required:

-

High Power Density Requirements: Each system required (5–10) 293kW power racks, with each 43U rack containing 24 AC-DC converters and control electronics. This translates to a high-density solution of over 16.5kW per U of rack space.

-

Liquid Cooling: Due to the extreme power levels and environmental conditions, forced air cooling was not an option. A fully liquid-cooled solution with strict pressure drop and flow requirements (48GPM, 35°C, 2–3psi drop) was necessary.

-

MIL-STD Reliability: The units had to comply with transportation shock and vibration standards across air, land, and sea, requiring robust mechanical construction and vibration-tolerant electrical components.

-

Electrical Complexity: The power system needed to operate from a 480VAC 3-phase input, delivering a regulated 380VDC output to 24 system loads, while also managing power factor correction, harmonic distortion, and digital communication between subsystems.

-

Aggressive Timeline: The customer faced a compressed development schedule that required an off-the-shelf solution with minimal integration risk.

Astrodyne TDI was brought in not just to supply power hardware, but to engineer a complete, field-ready solution.

The Solution: Engineering a Scalable Platform Together

As soon as the requirements were defined, Astrodyne TDI’s engineering team jumped in—not just to supply power modules, but to co-develop a solution with the customer’s electrical and mechanical teams. The program needed a high-density, reliable platform that could be deployed quickly and scaled easily. Instead of starting from scratch, we recommended building the system around two of our proven, off-the-shelf platforms: the LiquaBlade™ liquid-cooled power supply and the eLink2™ system controller.

LiquaBlade offered the power density, ruggedization, and liquid cooling performance the program demanded—delivering 16.5kW per 1U with full power factor correction, wide input range, and hot-plug compatibility. But what truly set it apart was its ability to reduce the size and weight of the system by nearly a third compared to traditional line-frequency solutions. At the same time, the eLink2 control interface allowed the customer to manage the full cabinet power system through a centralized, responsive control layer—complete with real-time monitoring, configurable I/O, and digital communication protocols like MODBUS TCP and CAN Bus.

Throughout development, our engineering team worked side-by-side with the customer’s program leads. We advised on breaker selection, coolant loop design, cable management, and system layout. Our goal wasn’t just to deliver parts—it was to deliver confidence. Together, we built a scalable, rack-level power infrastructure that the customer could plug directly into their phased array platform with no surprises.

Rack-Level Integration with System-Level Control

Each complete rack solution consisted of a 43U cabinet housing 24 LiquaBlade power modules and a 2U eLink2 interface module. Key system features included:

-

Dual 440VAC, 3-phase input feeds (220A each) with 250A circuit breakers

-

24 dual-pole DC breakers per cabinet for individual load protection

-

Liquid cooling loop rated for 48GPM with maximum 50psi pressure and 2–3psi pressure drop

-

Shock/vibration compliance to MIL-STD for transportation by land, sea, or air

The Final System: A Power Cabinet Ready for the Battlefield

The end result was a fully integrated 43U power cabinet, engineered for deployment across land, sea, and air platforms. Each cabinet housed 24 LiquaBlade modules and a 2U eLink2 controller, delivering a total system capacity of 293kW per rack. The cabinets were designed to accept dual 440VAC, 3-phase inputs, each protected by 250A-rated circuit breakers, and to distribute 380VDC through 24 dual-pole DC breakers for load-level protection.

Cooling was fully liquid-based, with a 48GPM coolant loop designed to maintain stable performance under continuous thermal load. We worked closely with the customer to meet pressure drop constraints and ensure long-term reliability, even under transport vibration and shock conditions. Each cabinet was wired and assembled with mission-ready reliability in mind, and conformed to MIL-STD shock and vibration requirements to survive the rigors of deployment.

What made the final system truly unique was not just the hardware—it was the collaboration behind it. Astrodyne TDI didn’t just deliver a product. We became a partner, ensuring that power infrastructure was one less thing the customer had to worry about as they focused on optimizing their phased array performance. With every wire, every breaker, and every interface, our goal was to make their innovation possible.